Welcome to Kings Rock Tools - Home of the Rock Drilling Tools!

Henan Kings Rock Tools Hollow Steel Semi-continuous Rolling Process

Release time:

Mar 30,2025

Source:

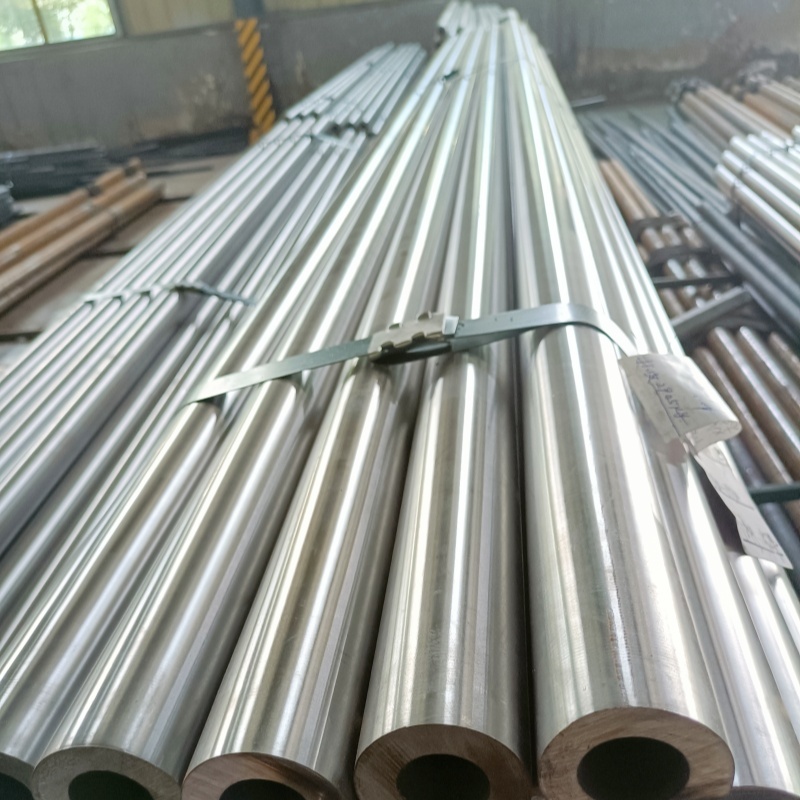

Hollow steel is the raw material for the manufacture of drill rods, and it is a kind of steel with high requirements for product quality. As a hollow steel production enterprise with many years of production experience, Henan Kings Rock Tools recognizes that the lack of hollow steel market at home and abroad is not quantity but high-quality products, who can have high-quality hollow steel in the rock tools market, who can occupy a place . Therefore, from the beginning of 2013, we began to plan the implementation of hollow steel rolling system technical renovation project for drilling tools, the use of advanced technology and equipment, the production process in line with the special process technology of hollow steel rolling deformation law, and meet the needs of market users in terms of variety, quality and production scale.

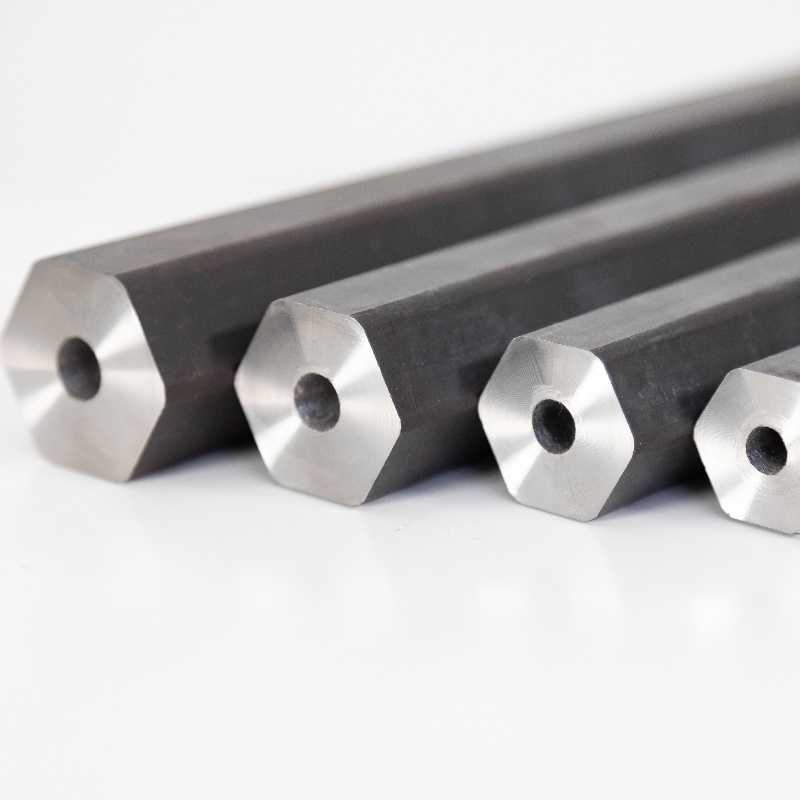

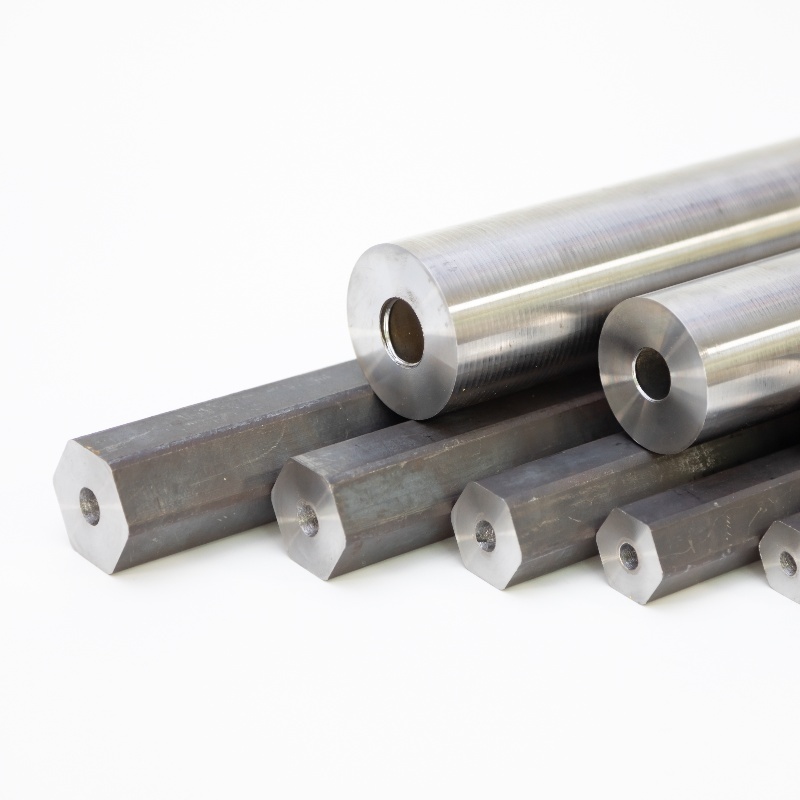

Mechanical drilling and semi-continuous rolling ensure that the dimensional accuracy of hollow steel meets the requirements, so that the hollow billet inside and outside the metal deformation uniform during rolling, to ensure that the finished steel products meet the process design requirements. Hollow steel rolling material is 55SiMnMo and 23CrNi3Mo, rolling specifications H22, H19 light drill rod.

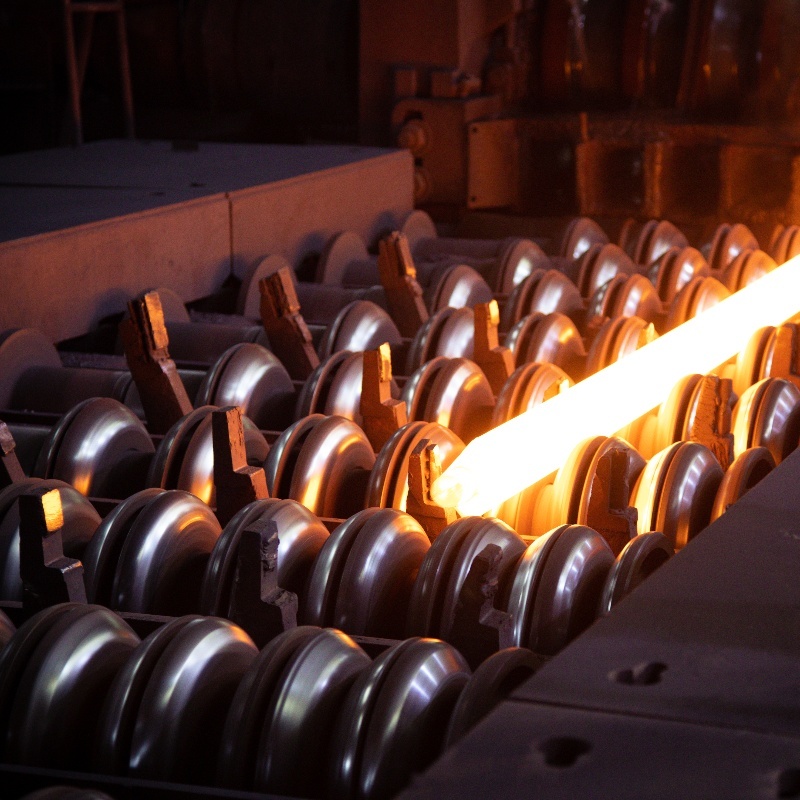

Semi-continuous hollow steel rolling production line adopts 150x150mm billet, round and square billet can be selected, center drilling method, remove core defects, insert mandrel and tube, heat treatment and rolling with core, in order to meet the deformation characteristics of hollow steel drilling, the average elongation of about 1.2, the total rolling passes 21.

The roughing and middle rolling adopts two-high reversing mill, and the finishing rolling group is continuous horizontal and vertical alternating 7-tandem rolling mill. In this process, the high temperature deformation section of the billet is set on the reversible roughing mill with large roll diameter, so as to realize the roll-by-roll rolling with proper deformation extension. It is easy to realize temperature control by placing the deformation rolling in the phase change temperature range of rolled pieces in 7 horizontal vertical roller alternating tandem rolling units, and ensure the metallographic structure of the hollow steel with certain properties.

Hollow steel special pass, rhomb-rhomb extension hole and hexagonal hollow steel special finishing rolling pass and round hollow steel finished and sizing pass.

By controlling every detail in the production process of hollow steel, a strict process system and quality system are formulated, and the performance index of hollow steel is further improved in the rolling process, which provides a guarantee for the production of high-quality drill rods.

Key words:

Related News