Welcome to Kings Rock Tools - Home of the Rock Drilling Tools!

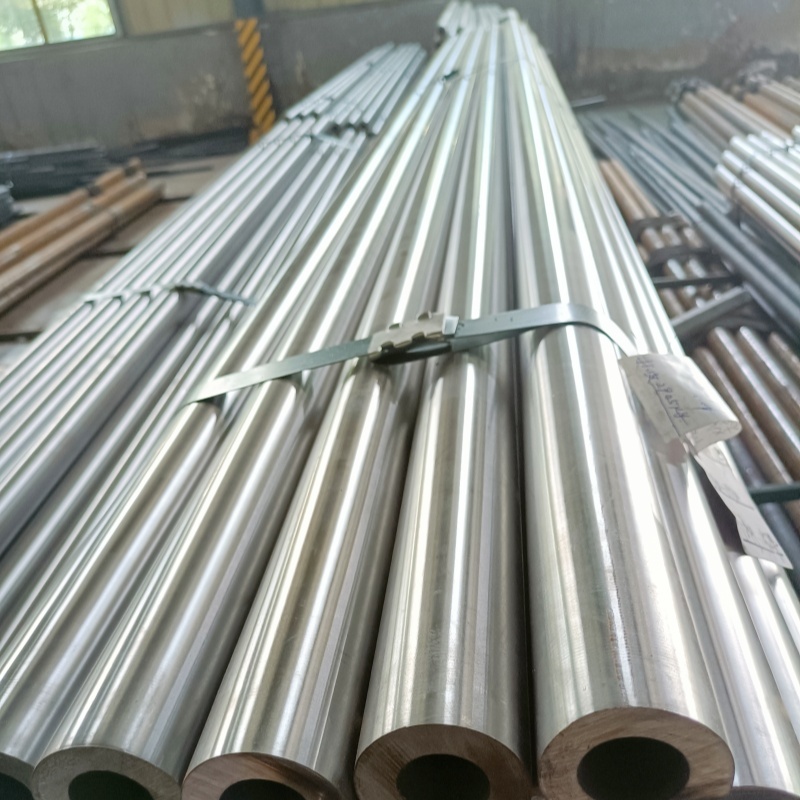

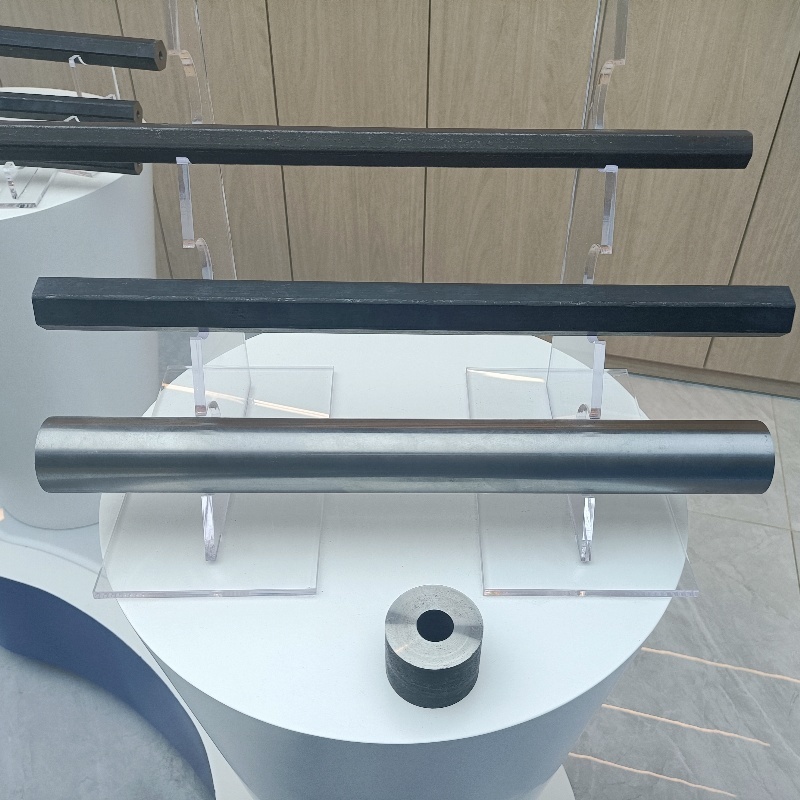

Advantages of Using Hot Piercing and Hot Rolling Process for 23CrNi3Mo Hollow Steel

Release time:

Mar 01,2025

Source:

Advantages of Using Hot Piercing and Hot Rolling Process for 23CrNi3Mo Hollow Steel

1.Efficient Forming

The hot piercing and hot rolling process softens the material at high temperatures, enabling rapid processing of billets into hollow steel, resulting in high production efficiency and suitability for mass production.

2.Improved Material Properties

During the hot piercing and hot rolling process, the material undergoes high-temperature deformation and recrystallization, leading to refined grains and a uniform internal structure. This enhances the strength, toughness, and fatigue performance of the hollow steel.

3.Material Savings

The hot piercing and hot rolling process directly processes hollow steel billets, reducing material waste, which is particularly beneficial for high-cost alloy steels like 23CrNi3Mo.

4.Good Surface Quality

The hot piercing and hot rolling process can produce smooth inner and outer surfaces, reducing the need for subsequent processing (such as grinding or polishing) and lowering production costs.

5.Adaptability to High-Strength Materials

23CrNi3Mo has high hardness and strength. The hot piercing and hot rolling process effectively processes such difficult-to-deform materials by softening them at high temperatures.

6.Mature and Reliable Process

The hot piercing and hot rolling process is a mature technology that ensures stable product quality, making it suitable for processing high-strength alloy steels.

7.Cost-Effectiveness

Compared to other methods (such as mechanical drilling or cold drawing), the hot piercing and hot rolling process has lower equipment investment and operating costs, making it suitable for large-scale production.

8.Adaptability to Complex Structures

The hot piercing and hot rolling process can flexibly adapt to different processing needs, making it suitable for producing hollow steel products with complex structures.

9.Enhanced Product Performance

Hollow steel produced through the hot piercing and hot rolling process has a uniform internal structure and refined grains, significantly improving fatigue resistance, torsional strength, and durability.

10.Environmental Friendliness

The hot piercing and hot rolling process generates less waste, which is easy to recycle and process, meeting environmental requirements.

Summary:

For high-strength alloy steel like 23CrNi3Mo, the hot piercing and hot rolling process offers advantages such as efficient forming, improved material properties, material savings, and high cost-effectiveness in the production of hollow steel. It meets the manufacturing requirements for high-quality hollow steel products, making it an economical and efficient choice.

Key words:

Related News